PHYSICAL METHODS OF STERILIZATION

PHYSICAL METHODS OF STERILIZATION

PHYSICAL METHODS OF STERILIZATION

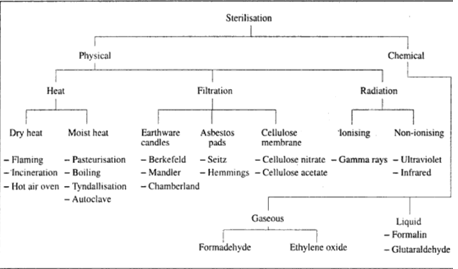

HEAT

Flaming

Red heat

Incineration

Hot air oven

Moist Heat

Water at 60-65°C

Water at 100°C (Boiling)

Steam sterilization Steam

(A) Steam at 100°C

(b) Low temperature steam at 80°C

(c) High temperature steam ( steam under pressure, autoclave)

RADIATION

I. Non-ionizing radiation

2. Ionizing

radiation Non-ionizing Radiation

PHYSICAL METHODS OF STERILIZATION ARE:-

HEAT

Heat is the most rapid, and best method of sterilization. It is the method of choice if the material to be sterilized is stable enough to withstand the required temperature necessary to kill the microbes.

The time needed for sterilization depends on the initial number of organisms present (hence washed and clean items are easier to sterilize than dirty ones) and also on the temperature used. Higher the temperature, shorter the time needed.

Heat kills bacteria by coagulation of their proteins. Different types of bacteria show differences in heat susceptibility. Spores need high temperatures while vegetative bacteria can be destroyed at lower temperatures.

Dry Heat this is the preferred method for sterilizing glassware’s, e.g. glass syringes and materials such as oils and powder which cannot be penetrated by water or steam. Dry heat is applied in the following ways:

1. Flaming

- the articles are passed through the Bunsen flame. The articles need not become red hot. It is used for scalpels, mouths of culture tubes, glass slides and points of forceps. It is of limited immediate use as only the surfaces touched by the flame are sterilised.

2. Red heat

Inoculating wire loops and needles are heated in the Bunsen flame until red hot. This is also of limited immediate use.3. Incineration

Micro-organisms exposed to open flames are burnt and killed. This is ideal for the carcasses of infected animals.4. Hot air oven

This is an oven that has a double walled chamber with a stout door, and it is electrically heated and thermostatically controlled. The oven contains a built in ventilator which disperses volatile matter during sterilization. A built-in fan inside helps circulate air in the oven so that the materials are evenly heated.

Sterilization times of three hours at 140 °C, one hour at 160 °C and 30 minutes at 180 °C are

commonly employed. The hot air oven is ideal for all dry glassware,

non-absorbent cotton wool, paraffin oil, and powder.

It is not

useful for culture media, liquids, rubber connections, glass to metal fitting

and fabrics, e.g., masks, towels, or gowns.

Moist Heat

1.Water at 60-65°C

At 60-65°C, water will kill most vegetative organisms. It does not fully sterilize but drastically reduces the number of pathogenic bacteria. This low temperature of water is useful mainly in the pasteurization of milk and in the preparation of some heat killed bacterial vaccines. It is also employed as one of the wash cycles in laundry and dish-washing machines.2. Water at 100°C (Boiling)

Boiling water at 100°C is frequently used in an emergency in the wards, to sterilize syringes, scissors and forceps. Most vegetative bacteria will die in 5-10 minutes when immersed in boiling water, but some spores will survive at this temperature for several hours.

The addition of sodium carbonate enhances

the sterilizing power of water and helps to prevent rusting. Articles sterilized by this method cannot be stored for a long time. It should be remembered

that the boiling point of water at a high attitude may be far below 100°C and

so boiling must be undertaken for longer time.

3. Steam sterilization Steam

sterilization is the most effective technique of moist heat sterilization and it can be applied in three ways.

(a) Steam at 100°C Steam at 100°C is usually achieved in the Koch

steamer which is a vertical metal cylinder with a conical lid. It is fitted

with a thermometer and has a small opening for the steam to escape.

Atmospheric steam at 100°C is used for the disinfection of some

large items of equipment's such as animal cages, and in dairy industry for the

disinfection of milk churns. Properly carried out, it should kill all

vegetative organisms but not the spores.

(A) Steam at 100°C

is also employed to sterilize carbohydrate media. The procedure employed is called Tyndallization after Dr. John Tyndell who devised the method. The materials are exposed in their final containers to free steam at 100°C for 30 minutes on each of three successive days. After steaming, the materials are left at room temperature until the following day when the process is repeated until three successive steaming have been doneThe principle

is that all vegetative bacteria are killed by the first steaming. After 24 hours at room temperature, the surviving spores will have started to grow into heat sensitive vegetative forms. These will be killed by the second exposure. The third and final steaming is to ensure a total elimination of any remaining spores that may have germinated.(b) Low temperature steam at 80°C

Water will boil at less than 100°C if the atmospheric pressure is reduced. Steam at 80°C is used to sterilize such articles that cannot withstand the normal heat sterilization procedures. Such articles include blankets, mattresses and certain surgical instruments. Special autoclave operating at reduced pressure is used to achieve this. To enhance sterilization, formalin vapour is introduced into the autoclave during the processing cycle.(c) High temperature steam ( steam under pressure, autoclave):-

This is steam above 100°C and it is the most efficient means of sterilization. It is routinely used for most heat-stable materials. An autoclave is used to achieve the high temperature steam. The boiling point of water is raised by increasing the pressure inside the autoclave. There are different designs of autoclaves in the market. But basically the autoclave is a double-walled or jacketed chamber that can withstand the high pressures requiredThe autoclave has a steam inlet valve and a steam outlet valve. In addition, it is usually equipped with a safety valve (set to open at a per-determined pressure), a temperature gauge and pressure gauge. The usual sterilization temperature is 121°C at 15 lbs per square inch (psi) pressure for 15 minutes. Greater the pressure, higher the temperature and shorter the time of sterilization.

for more about autoclave click here

It is ideal for sterilizing a large number of articles such as syringes in a comparatively short time. The articles are packaged in metal containers and passed through an insulated chamber and then exposed to infra red radiation where they are sterilized at 190°C for 10 minutes.

for more about FILTRATION - CLICK HERE

RADIATION

Radiation used for sterilizing purposes falls into two

groups:

I. Non-ionizing radiation

2. Ionizing

radiation Non-ionizing Radiation

Non-ionizing radiation

is provided by ultra-violet and infra-red rays. Infra-red radiation They are of low energy type and are electromagnetic rays with wavelengths longer than those of visible light. It kills micro organisms by oxidation as a result of heat generated. It is in fact a form of hot-air sterilization.It is ideal for sterilizing a large number of articles such as syringes in a comparatively short time. The articles are packaged in metal containers and passed through an insulated chamber and then exposed to infra red radiation where they are sterilized at 190°C for 10 minutes.

Sterilization control A type of Browne's control tube is used to control the sterilization.

It changes from red to green after 12 minutes at 180°C Ultraviolet light

Electromagnetic radiation with wavelength between 100 and 400nm is called

ultraviolet (UV) light. The rays of wavelength between 240 and 280 are absorbed

by nucleic acids. This energy absorption induces chemical changes that alter

the structure of the DNA and leads to the death of the cell.

Most UV

radiation does not readily penetrate glass, opaque solids or liquids. It is

generally used to sterilize surfaces in work areas such as media pouring room

and safety cabinets, or air in surgical rooms. Gram negative bacteria are more

susceptible to UV radiation than Gram positive ones. Spores are highly

resistant. Low pressure mercury vapor lamp can be used to produce UV light in

the laboratory.

The rays

should not be allowed to come in contact with the eyes. Ionizing Radiation Ionizing radiation, unlike the UV radiation, penetrates non-living and living

organisms readily. Sterilization is achieved without appreciable rise in

temperature. Therefore, it is also referred to as 'cold sterilization'.

It is used

to sterilize heat-sensitive medical supplies such as plastic syringes, drugs

and a wide range of disposable items. Cathode rays and gamma rays (from cobalt

60) are the most effective ionizing radiation. It is expensive and very

dangerous.

Sterility

control Spores of Bacillus subtitles are recommended for use for sterilization

control of ionizing radiation.

FILTRATION- Filtration as a physical means of sterilization is effective

and reasonably economical. It is used to sterilize heat-sensitive fluids, and

air. It is particularly useful for solutions containing toxins, enzymes, drug,

serum and sugars.

Sugar

solutions used for the cultivation of micro-organisms tend to caramelize during autoclave and so they are best filter-sterilized.

Filtration is also used extensively in beer and wine industries. Filter with known pore sizes sufficiently small to hold back bacteria are employed. Recently filters that can remove viruses as well are available.

Filtration is also used extensively in beer and wine industries. Filter with known pore sizes sufficiently small to hold back bacteria are employed. Recently filters that can remove viruses as well are available.

Several

types of materials have been found useful in microbial filters such as

diatomaceous earth (in Berkefeld and Mandler filters), porcelain (in Chamber land filters), Sintered glass, asbestos (in Seitz and Hemmings filter)

and cellulose ester (in membrane filters).

for more about FILTRATION - CLICK HERE

If you have any queries related medical laboratory science & you are looking for any topic which you have have not found here.. you can comment below... and feedback us if you like over work & Theory

.

Thanks for coming here..