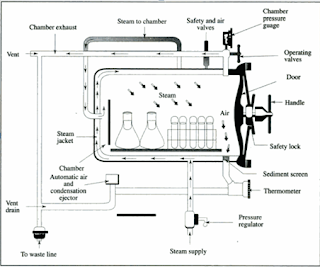

Autoclave:- This is steam above 100°C and it

is the most efficient means of sterilisation. It is routinely used for most

heat-stable materials. An autoclave is used to achieve the high temperature

steam. The boiling point of water is raised by increasing the pressure inside

the autoclave. There are different designs of autoclaves in the market. But

basically the autoclave is a double-walled or jacketed chamber that can

withstand the high pressures required The autoclave has a steam inlet valve and

a steam outlet valve. In addition, it is usually equipped with a safety valve

(set to open at a pre-determined pressure), a temperature gauge and pressure

gauge. The usual sterilization temperature is 121°C at 15 lbs per square inch

(psi) pressure for 15 minutes. Greater the pressure, higher the temperature and

shorter the time of sterilization.

The cycle however

depends on the volume of material to be sterilized and the amount of

contamination expected. It is recommended that large volumes of material such

as culture media or surgical dressings, be dispensed into small volumes or

portions to reduce the time required for sterilization and so decrease the

chance of over cooking or damaging the material.

Although

autoclaving is a highly recommended method of sterilization, its major

drawbacks are that it may cause damage to heat-sensitive materials, and the

load is not dried.

The domestic

pressure cooker is the simplest form of autoclave. The steam displacement

autoclaves which used to be the commonest type, are

becoming

obsolete. A mastery of the operation of all types of autoclaves is essential to

avoid major accidents due to explosion and to prevent over heating of the

material.

Operating an autoclave

The load is

loosely placed in the chamber and the door or lid securely shut. Both the inlet

and outlet valves are open. Steam is introduced into the chamber to force air

out from it, leaving only pure steam. (A rubber tubing attached to the outlet

valve with the end dipped in a bucket of water will stop bubbling when all the

air has been forced out).

Close the

outlet valve, the temperature and pressure will begin to rise. When the desired

temperature and pressure are reached, close the inlet valve. Start to time the

sterilisation cycle to the desired length of time.

This period

of actual sterilisation is known as the 'holding time'. At the end of

sterilisation, open the outlet valve slowly to avoid boiling over of liquid

media. The steam begins to escape and at the same time the temperature and

pressure begins to fall. Never open the autoclave until the pressure is

completely down in order to avoid explosion.

The high vacuum

autoclaves are fast and reliable. Before the admission of steam, 98 per cent of

the air present in the chamber is rapidly removed by electric pump and

sterilisation can proceed without delay. The cycle is short and heat

penetration is efficient. Most of the newest models of autoclaves are fully

automatic. The operator simply loads the autoclave, presses the start buttons

and the autoclave is left unattended to till the cycle is completed.

This table shows the

relationship between time of autoclaving, pressure and temperature.

Pressure,

holding time and tempreture for autoclaviing

|

||||

Gauge pressure(PSI*)

(pressure above atmospheric)

|

Holding time (min)

|

Temperature(*C)

|

||

Pure steam (no air present)

|

50% air-steam mixture

|

No air removed

|

||

5

|

40

|

108

|

94

|

72

|

10

|

30

|

115

|

105

|

72

|

15

|

15

|

121

|

112

|

100

|

20

|

10

|

126

|

118

|

109

|

25

|

5

|

130

|

124

|

115

|

30

|

5

|

134

|

128

|

121

|

Testing the efficiency of the autoclave

There are

several methods of testing whether or not material is adequately sterilised.

The four commonest methods are:

1. Brown's sterilizer

control tubes These are tubes containing an indicator liquid and designed for

steamer, hot air oven and autoclave. The liquid will change from red to green

if the correct temperature time combination has been employed; if not, the

liquid turns a reddish-brown color. The tubes are placed in the area of least

heat penetration.

2.

Biological indicator Filter paper strips impregnated with a sporing organism

such as Bacillus stear other mophilus, is enclosed in an envelope and placed at

the centre of the load to be sterilised. On removal, the strip is cultured in a

suitable medium and incubated at 55°C for one week. No growth indicates proper

sterilisation. This method is good when time factor is not important because

the organism requires long incubation to grow.

3. Autoclave

tapes There are many tapes based on the Bowie-Dick autoclave tape principle of

uniform colour change. The tape indicates the degree of heat penetration. The

tapes have a water resistant gummed side. When sterilisation is adequate and

complete, the tape changes colour uniformly. While the Bowie-Dick tape does not

test for adequate exposure to heat in terms of time and temperature, strips of

tapes may be useful on individual packages as indicators of exposure to heat.

4.

Thermocouples The efficiency of an autoclave is best monitored by means of

thermocouples which are placed within the contents and calibrated to show the

temperature attained.

Sterilisation failure in the autoclave

Sterilisation failures may be due to:

1. Incomplete removal of air from the autoclave. Temperature

of air/steam mixtures at a given pressure is lower than that of pure steam

2. Incorrect methods of packaging.

3. Careless loading into steriliser.

4. Failure to time correctly, the proper period of exposure

(holding time).

5. Attempts to sterilise materials impervious to steam in an

autoclave, e.g., oils.

6. Faulty equipment.

Inspissation: This is the method of coagulating and

further sterilizing culture media that were initially prepared aseptically. The

media should contain a coagulable protein such as serum or egg. It is ideal

therefore for Loeffler's medium or Lowestein Jensen's medium.

The

inspissator is a double walled copper box with water flowing between the two

walls.

The inside

is made in such a way that culture media bottles lie slopped. The temperature

is controlled between 75-80°C thermostatically. Inspissation is carried out for

two hours on each of three consecutive days. A higher temperature may denature

the protein and cause bubbling of the surface of the media.

If you have any queries related medical laboratory science & you are looking for any topic which you have have not found here.. you can comment below... and feedback us if you like over work & Theory

.

Thanks for coming here..