Quality Assurance System, External and Internal Quality assurance

Quality Assurance System

They are:

2. Analytical factors:

3. Post analytical factors:

PRE ANALYTICAL FACTORS

1. Patient Identification and Preparation

2. Specimen Collection, Transportation and Storage

3. Specimen Receiving and Recording in the Laboratory

ANALYTICAL FACTORS

- Internal Quality ControlMaintenance of equipmentReagents, standards and calibratorsControl materialLinear rangeMethod evaluationMeasurement of inaccuracyApplication of quality control systemControl rulesExternal Quality Control

POSTANALYTICAL FACTORS

Quality Assurance System

Quality

assurance system (QAS) can be defined as all the systematic actions necessary

to provide adequate confidence that laboratory services will satisfy given

medical needs for patient care. It encompasses factors in three different

areas.

They are:

1.

Preanalytical factors: These factors occur outside the laboratory and include

patient preparation and collection, handling and storage of specimens before

processing.

2. Analytical factors: These can be controlle by an efficient quality control system within the laboratory by recognising and minimising analytical errors.

3. Postanalytical factors: These consist of recording and transmitting patient data to the physician in a fashion which can be interpreted correctly.

- Therefore, delivery of accurate results is an outcome of co-ordinated interdepartmental group approach. Besides accuracy in laboratory testing, other quality characteristics involve non-laboratory personnel such as physicians, nursing staff and clerical staff.

- Those outside the laboratory help in the QAS by providing effective test request forms, clear instructions for patient preparation and specimen handling and appropriate time interval for specimen processing, testing and result reporting so that result reports can be sent to the physician with reference ranges for proper interpretation and patient care.

PREANALYTICAL FACTORS

1. Patient Identification and Preparation

Before a

sample is taken, the patient should be positively identified by verifying his

name and identification number.

- The laboratory should provide a procedure manual containing information regarding each test, from how to request a test to any instructions that should be followed before and while a sample is being collected.

- This manual should be available to all medical and nursing staff. Patient preparation may include instructions about nutritional status, alcohol, drugs, smoking, exercise and sleep.

2. Specimen Collection, Transportation and Storage

The method

and time of specimen collection depend on the nature of the test requested. The

laboratory guidelines in the manual should be strictly adhered to for specimen

collection.

- The type of anticoagulant used for blood samples and containers used will vary with the nature of the test. It may be necessary to use more than one sample containers per patient. Each tube should be labelled with patient's name, identification number, and the date and time of sample collection.

- Once collected, the specimens should reach the laboratory in a timely manner without unnecessary delay. Sometimes, the temperature at which the specimen should be transported is also critical.

3. Specimen Receiving and Recording in the Laboratory

When a

sample arrives in the laboratory, it should be received either by logging in

the computer or by recording in a register with a laboratory reference number.

ANALYTICAL FACTORS

After the

samples are properly logged in and distributed for testing, analytical system

checks are implemented to ensure that the results are accurate.

Quality

control should set limits and directions for the laboratory scientists involved

in performance of the test. This can be achieved by constantly monitoring the

quality control system through:

1. Internal quality control.

2. External quality control.

Internal Quality Control

The internal

quality control can be maintained by going through a complete checklist of

items to make sure that all laboratory systems are being monitored and in

control. This checklist includes:

(i)

Maintenance

of equipment and glassware

(ii)

Quality control of reagents, standards,control

materials and reference ranges.

(iii)

Method

selection and evaluation

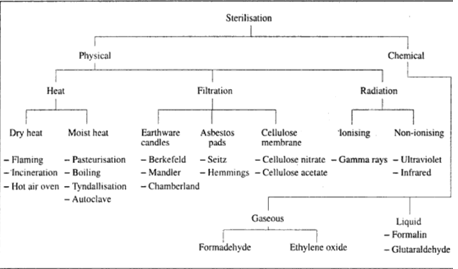

Maintenance of equipment

• To ensue that all instruments are performing up to

expected standards, a schedule of daily and monthly preventive maintenance for

each piece of equipment is essential.

- A scheduled maintenance sheet for each instrument should be available for the regular check-up of operating instructions. Tolerance limits for each test should be specified so that malfunctions can be detected.

- The temperature of all thermostatically controlled instruments such as water baths, refrigerators and freezers, incubators, ovens, autoclaves and dry heating blocks should be recorded daily or just before use.

- Balances, mechanical pipettes and glass pipettes should be properly maintained and calibrated on regular basis. Glassware should be cleaned properly and discarded when it becomes chipped or cracked.

Reagents, standards and calibrators

- Reagents and kits should be dated when prepared orreceived; and also when they are brought in use. New lots of reagents should run in parallel with old reagent lots before being used for analysis.

- The dependability of a method to give reliable results depends on the quality of the reagents used for calibration and standardisation. The most highly purified chemicals should be used.

- For some analyses, certified reference materials (CRM) are used to develop, verify and calibrate the reference methods. The calibrators should have their concentrations assigned through the use of either reference methods or other very specific methods.

The comparative analysis of the calibrator and the specimens provides the basis for calculating values for patientspecimens.

Control material

Control materials should be analysed as unknown samples to monitor calibration of methods and instrumentation. The same tect the specific analyte of interest. Specificity can be expressed as:

where TN is

true negative and FP is false positive.

Linear range Linear range is the concentration

range over which the measured concentration is equal to the actual

concentration without modification of the method. A wide linear range is

preferred.

Method evaluation In method evaluation, imprecision

and inaccuracy of a method are determined and compared with the maximum error

all-owed on the basis of medical criteria. If they fall outside the limit, the

test is either rejected or modified.

Measurement

of imprecision Imprecision is the dispersion of repeated measurements around

the mean and is due to the presence of random analytical error. It is the

inability to produce the same result from the same specimen on repeated

estimations. Imprecision can be detected by analysing a group of patient

specimens along with controls over a period of 20 days. Once the data is

collected, the level of imprecision can be determined

Measurement of inaccuracy Inaccuracy is the difference between

the measured value and its true value and is due to systematic analytical

error. If the degree of imprecision is acceptable, the degree of inaccuracy can

be estimated by comparison-ofmethods experiment. In this method, the same

patient samples are tested by the method being evaluated and by a comparative

method. The best comparative method is the reference method which has

negligible inaccuracy. However, reference methods are very laborious and may

need specialised equipment. Therefore, the results of the new test method are

usually compared with those of the method in routine use. At least 40 to 100

samples must be run by both methods before reaching a conclusion. The results

can be interpreted either by plotting the graph using the data obtained by both

the methods to decide the degree of inaccuracy: or by applying the 'F' and 7'

test (refer to Section I Chapter 4). Figure 5.1 shows the schematic

representation of control data showing no analytical error (A): increased

random error (B) and increased systematic error (C).

Application of quality control system

The purpose of quality control system is to monitor analytical processes, detect analytical errors during analysis and prevent reporting of incorrect patient results. The monitoring is usually done by analysing stable control materials and then comparing the observed values with the expected values. The different levels of control material should be evaluated for at least 20 days. The means (X) and standard deviation (SD) of these control data are then calculated. Control values may be compared with statistical limits numerically or by display on a control chart. This chart is an extension of Gaussian distribution. The vertical axis (y-axis) is labelled with the control values and the horizontal axis (x-axis) is labelled with the days. The y-axis is scaled to provide a concentration range from x3SD to X + 3 SD. Each control result is plotted as a point intersecting the control SD and the day of the test (Fig. 5.2).

An

analytical method is said to be in control when there is a symmetrical

distribution of control values about the mean, and there are few values of

control outside the 2 SD limits. A sudden jump from the established mean to a

new mean is considered a 'shift'; whereas a slow deviation from the mean value

in either direction is considered a "trend'.

Each

laboratory may decide its own criteria for judging whether control results are

acceptable or not.

There are

some popular control rules which can help in decision-making.

Control rules

1. One control observation exceeds mean + 2

SD. This is

a warning rule.

2. One

control observation exceeds the mean

3 SD. This

is a rejection rule.

3. Two

consecutive control observations are on the same side of the mean and exceed

mean + 2 SD control limits. This is a rejection rule.

4. The

difference between two control observations within one run exceeds + 4 SD. This

is a rejection rule.

5. Four

consecutive control observations are on the same side of the mean and exceed mean

1 SD control limit. Reject the run.

6. Ten

consecutive control obser-vationsoccur on the same side of the mean. This is a

rejection rule.

External Quality Control

Internal quality control monitors daily quality

control in a laboratory whereas external quality control is a way to compare

the performance of a laboratory with reference to others. External quality

control is also known as proficiency surveys.

Such proficiency testingprogrammes periodically provide samples of unknown results to participating laboratories. When a laboratory receives such a sample, it must analyse and return the results within a specified period of time for comparison with the results obtained from other laboratories participating in the proficiency survey.

Such proficiency testingprogrammes periodically provide samples of unknown results to participating laboratories. When a laboratory receives such a sample, it must analyse and return the results within a specified period of time for comparison with the results obtained from other laboratories participating in the proficiency survey.

At the

proficiency survey centre, the results from each laboratory are compared to the

expected results or those obtained from a few reference laboratories.

The

comparison may be either with fixed limits or statistically derived limits. For

statistical comparison, the means and standard deviations of all the results

are computed.

The deviation from the mean is expressed as standard deviation indices (SDI) above or below the mean. The SDI is the numerical difference between the individual laboratory's result and the mean, divided by the standard deviation.

The deviation from the mean is expressed as standard deviation indices (SDI) above or below the mean. The SDI is the numerical difference between the individual laboratory's result and the mean, divided by the standard deviation.

A deviation

of more than + 2SDI requires investigative action, whereas a deviation of over

3 SDI is considered unacceptable. The participating laboratories must try their

best to determine the causes of the erroneous results. This will help the

laboratory to improve on the quality of its test results.

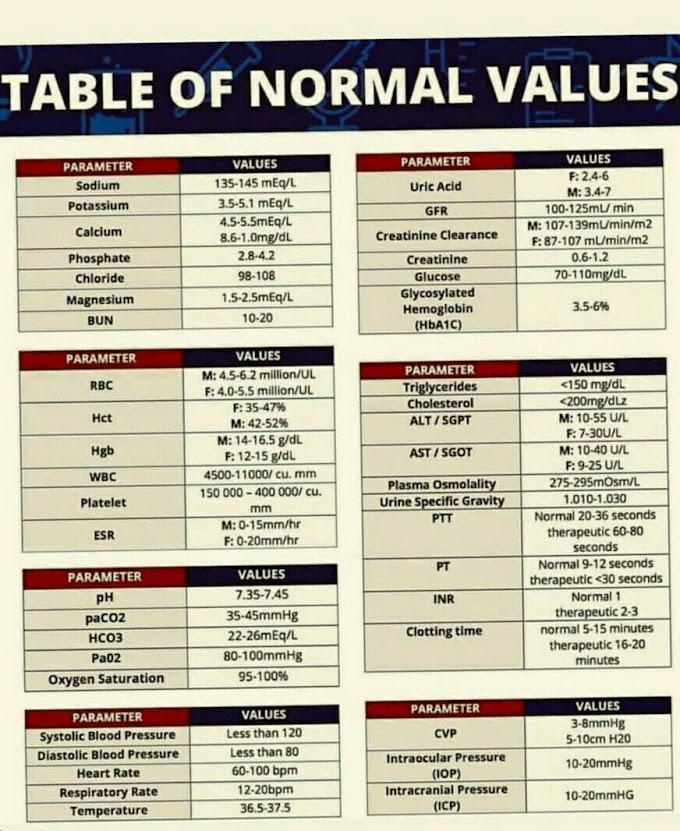

POSTANALYTICAL FACTORS

The postanalytical factors include recording and

transmitting patietn's results to the physician within reasonable time

interval. Once the results reach the physician, he has to decide whether they

fall within normal limits or not.

Therefore, the results should include the reference ranges, critical and technical limits. It is always helpful to check the critical values before reporting them. The reference values which vary with age and sex should be clearly indicated.

Therefore, the results should include the reference ranges, critical and technical limits. It is always helpful to check the critical values before reporting them. The reference values which vary with age and sex should be clearly indicated.

It is of

utmost importance to avoid clerical mistakes in the transmission of clinical

results to the physician. With the use of computer-generated patient reports,

such incidence can be considerably reduced.

If you have any queries related medical laboratory science & you are looking for any topic which you have have not found here.. you can comment below... and feedback us if you like over work & Theory

.

Thanks for coming here..